Tilt pouring - aluminium castings

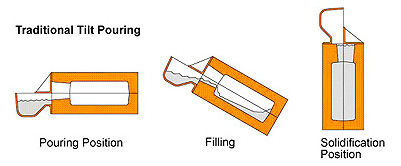

At casting by means of tilt pouring method, the pouring machine is tilted into the position in which the common line of mould and machine is horizontal.

This tilting of the machine is performed at the controlled speed so the metal enters the mould cavity at the controlled speed and with the minimum air intake that results in the inner casting purity.

Advantages

- homogeneous casting structure

- process repeatability

- better metal yield

- more stable pouring parameters

- low mould costs comparing to the high pressure casting moulds

- possible high automation level